Industry introduction

With the continuous deepening and refinement of production and processing in the petrochemical industry, in order to ensure safe production and avoid major accidents, the position of non-destructive testing technology in the petrochemical industry is particularly important.

Eddy current testing technology can be used in the oil industry (oil pipeline, rod, drilling rod, etc.) and chemical pipeline (such as stainless steel pipe, carbon steel pipe, titanium alloy pipe, etc.) raw material testing and in-service re-exploration testing, for the pipeline intergranular corrosion, wall thickness thinning and outer wall wear can be reliably detected.

Case application: Drilling rod

The role of the oil drill pipe is to transfer the tremendous torque of the oil rig to the drill bit while maintaining excellent sealing performance. Therefore, the quality requirements of oil drill pipe are particularly high, and corrosion and cracking are the most common and harmful defects in the drill pipe end area. If cracks are found, the drill pipe must be scrapped. Oil equipment is generally large in size, it is not easy to detect after processing, and it is also very difficult to repair when the test fails.

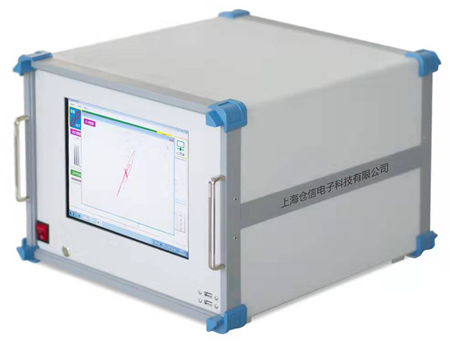

The high performance through and rotary eddy current inspection equipment produced by Cangxin NDT can detect the defects of oil drill pipe online during the early production and processing process, and can make timely intervention and adjustment to ensure the quality of the shipped products, so as to improve the service life of oil drill pipe and effectively reduce the production cost.

Case application: Sucker rod

The rod is the main force component of the mechanical oil production system in the oil field, which is in the environment of various corrosive media, and also bears various loads such as alternating vibration and impact, so it is easy to suffer corrosion damage and lead to rod fracture accidents. In addition, due to the metallurgical defects or inclusions contained in the rod itself and the non-standard heat treatment, fatigue cracks are easy to occur under the action of long-term alternating stress, and the transverse cracks on the surface are the main reason for the rod body fracture. According to statistics, the number of stoppage caused by rod fracture accounts for more than 20%, so the rod failure during the working period will bring great economic losses to the oil field.

The high performance through and rotary eddy current inspection equipment produced by Cangxin NDT can quickly and accurately detect the defects on the rod, effectively prevent rod breakage accidents, and reduce the loss of production.