Industry introduction

As one of the five conventional non-destructive testing methods, eddy current testing technology is widely used in steel production, including steel pipe (seamless pipe and welded pipe) inspection, steel rod inspection, steel wire inspection, billet inspection, plate and strip inspection, material identification and mixed steel separation.

In recent years, with the development of computer, instrument and digital signal processing technology, the application of automated eddy current nondestructive testing technology in iron and steel industry has made new progress.

Case application: Silver bright rod

It is usually used to detect spot defects or circumferential cracks on the surface and near the surface of steel, and to detect longitudinal cracks on the surface and near the surface of steel with rotating point eddy current probes. It is also possible to use rotating + passing eddy current probes at the same time to realize comprehensive detection of three common typical steel defects.

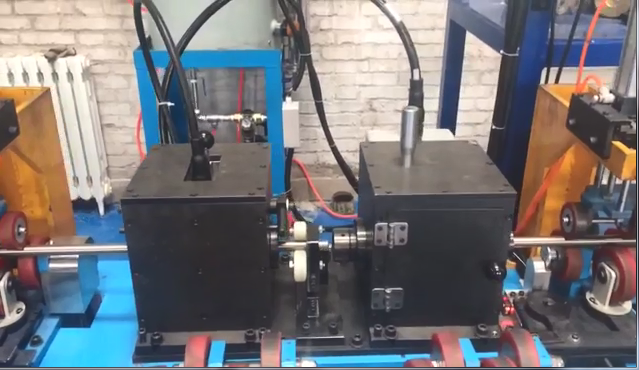

The ETC-10B high performance through and rotary eddy current inspection equipment produced by Cangxin NDT can quickly and accurately detect various defects existing on the surface of steel, and effectively improve the quality of steel products.